Step drilling from Lothmann in Ludwigsburg - Special tools made to measure since 1980

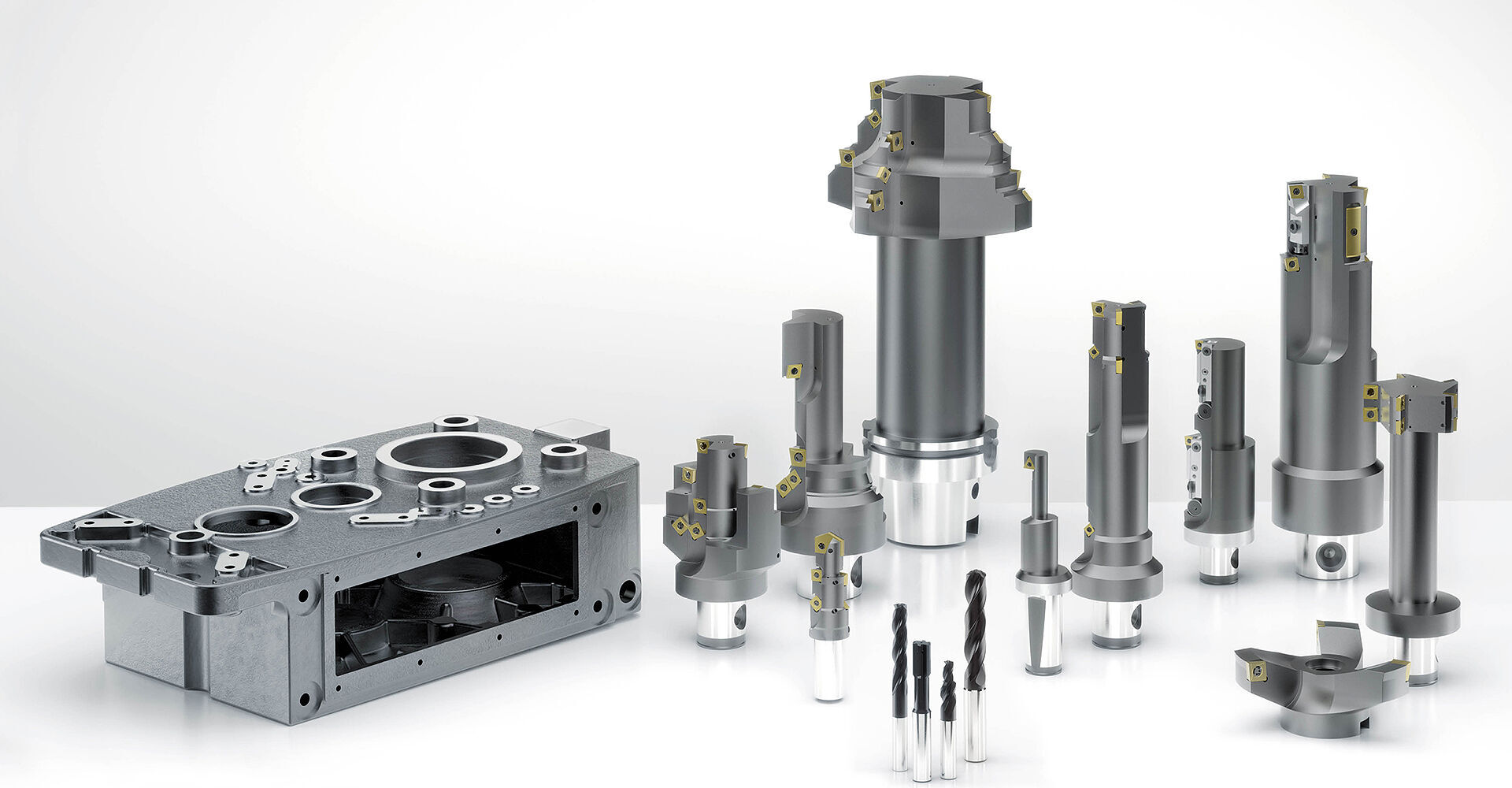

The company Lothmann Werkzeugtechnik GmbH & Co. KG, based in Ludwigsburg, has been the expert for the production of special tools, such as step drills, since the mid-1980s. The step drills are primarily suitable for drilling work, i.e. for drilling with inserts, drilling, spindling, chamfering, countersinking, reverse countersinking and for turning over as bell tools.

With Lothmann's products, the focus is on simultaneously machining as many different operations as possible on one bore on CNC machining centres.

The step drills can be used to machine various materials such as cast materials, especially grey cast iron or nodular cast iron, as well as steels of all kinds, such as low-alloy and high-alloy as well as stainless steel and non-ferrous metals such as aluminium or copper alloys.

Customised products That meet your requirements and specifications

All Lothmann step drills are equipped with radial ISO indexable inserts, which can be easily replaced after wear due to their standardisation. The inserts are made of carbide, which stands for consistently high precision and reliability as well as wear resistance and temperature stability.

It offers decisive advantages compared to HSS. For cutting steel, the inserts are additionally provided with a multiple coating.

The step drills can be used for rotating applications on a machining centre (BAZ) as well as on lathes in the form of a stationary tool. We need no more than a drawing extract and our completed checklist to design your step drill to fit precisely.

Thanks to our self-developed design environment, you already receive a drawing as a PDF including parts list and cutting value recommendations with every quotation.

The Lothmann step drills are produced in a CAD/CAM process.

Our step drills are manufactured using a special CAD/CAM process. Your requirements for our products are summarised and managed with all important parameters in a central file. All process steps are carried out with integrated software (CIM). This includes, for example, the creation of 2D drawings and 3D solids.

The recorded data can be used to simulate and test the step drill in 3D CAD. Subsequently, the drills are turned and milled CAM-controlled on the most modern 5-axis machining centres. For the final inspection, all step drills are 100 percent checked for dimensional accuracy on fully automatic Kelch and Mapal presetting devices.

All advantages at a glance:

- One hundred percent dimensional control

- Delivery within 3 weeks from receipt of order

- Functional guarantee

- Inexpensive custom-made products

- Enables multiple operations with only one drill bit

- No regrinding due to the use of ISO indexable inserts

Place your step drill order with us now - we look forward to receiving your order!