Application examples

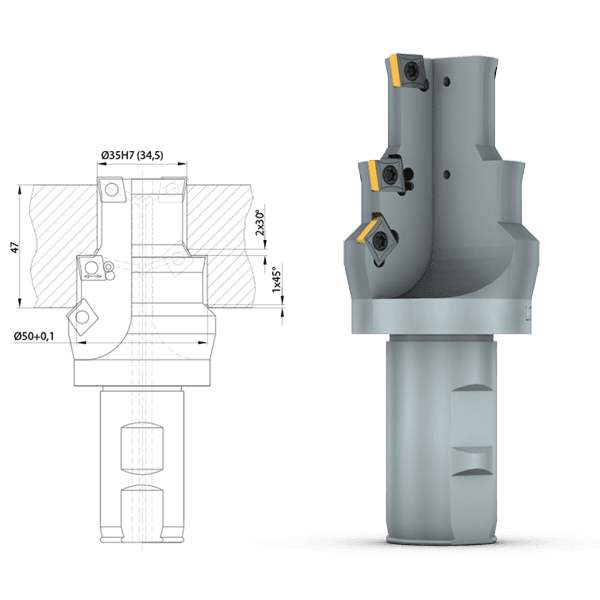

Drilling out

53 hours faster

Boring and chamfering of a pre-cast bearing bore on a gearbox housing made of GG25. The Ø35 H7 is then spindled.

Previously: reboring Ø34.5 and Ø50 each with a roughing two-flute cutter (cost approx. 2 x 950 €). Circular milling of the two chamfers.

New: 2 Lothmann step drills invested at 768 € each. Boring of both Ø and chamfers in one tool. 3 tool changes and 2 magazine places saved. Running time reduced by 0.8 minutes per part.

Savings after 4000 parts:

- 4000 parts x 0,8 min x 1,6 €/min

- 5.120 €

- 2 Lothmann step drills à 768 €

- 1.536 €

- Profit

- 2.624 €

+ Running time reduced by 53 hours

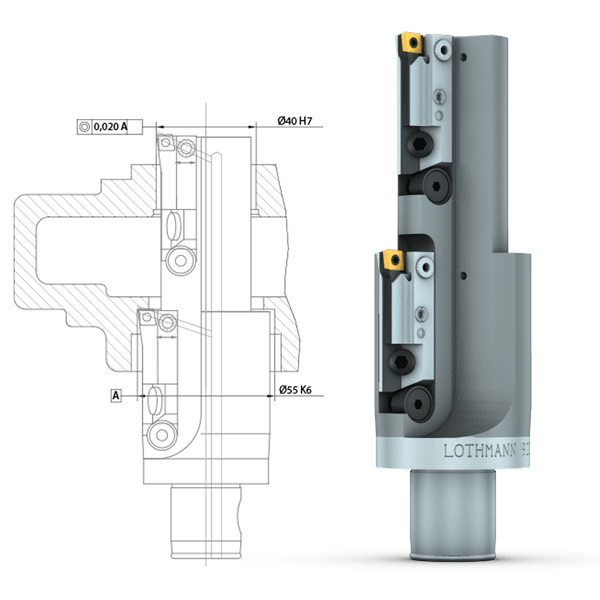

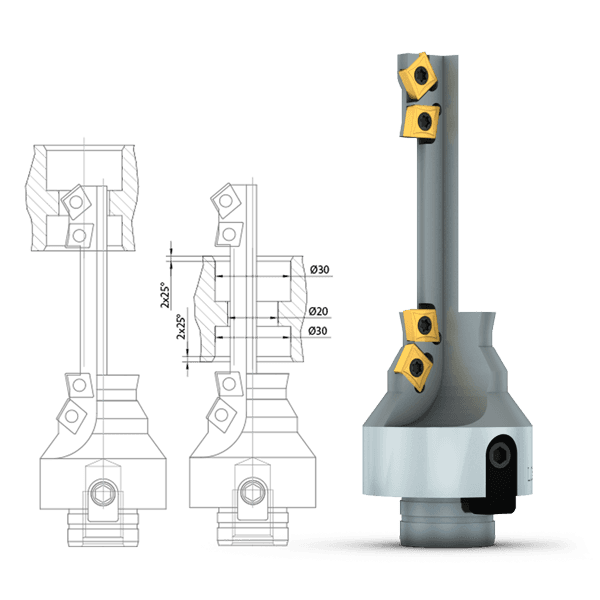

20 µ Alignment tolerance

Complete machining of a gearbox housing made of GGG50 on an older BAZ. The fits must be aligned within 20 µ.

Previously: Both fits are machined one after the other with fine turning tools. The tool change leads to alignment problems.

New: 2 Lothmann combination tools at 1231 € each were invested. The previous fine turning tools are free for other applications. Machining of both fits is done in one pass. The Ø55 starts when Ø40 is finished. Alignment is ensured. There is no need to change tools and one magazine space is freed up.

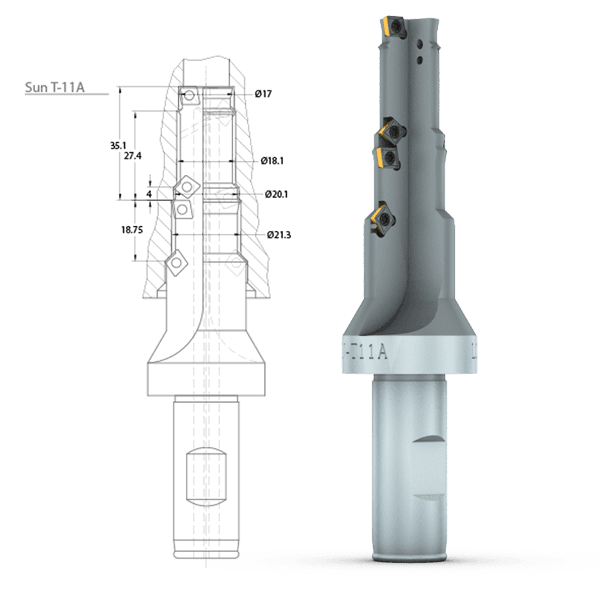

3 minutes faster

Pre-drilling of a screw-in hole for Sun T-11A valves in a cylinder base made of St52 (S355). The hole is predrilled with Ø13.5.

Previously: All diameters and chamfers are pre-drilled with an HSS form drill. Machining is tedious and wear-intensive because of the mild steel.

New: Purchase of 3 Lothmann step drills at 673 € each. ISO cutting inserts with special chipbreaking geometry to avoid winding chips. Five times feed rate and four times tool life compared to HSS.

Example savings:

- 800 parts x 3 min x 1,80 €/min

- 4.320 €

- Tool costs up to now: 2 HSS countersinks a 615 € + 1 regrind 150 €

- 1.380 €

- New: 3 Lothmann step drills a 673 €

- 2.019 €

- Profit

- 3.681 €

+ Running time reduced by 3 x 800 / 60 = 40 hours

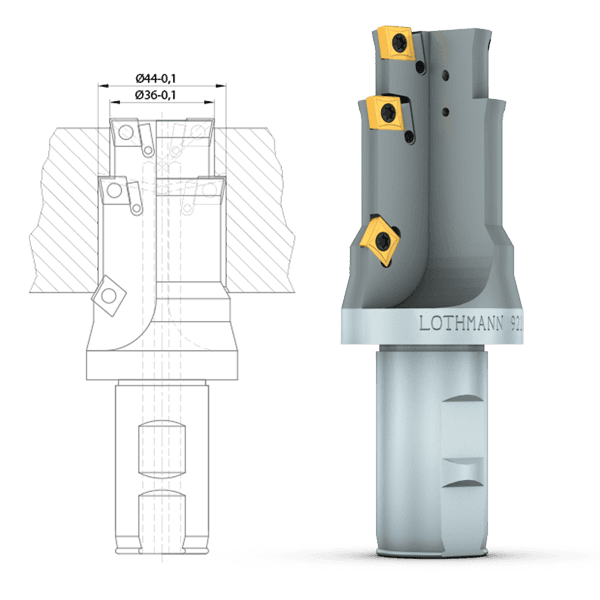

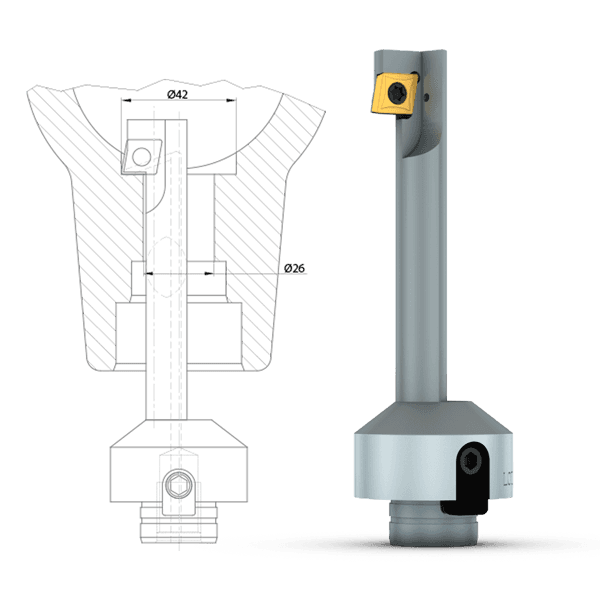

Diameter adjustable

Finish boring and chamfering of two diameters with 0.1 mm tolerance with normal sintered ISO inserts.

Previously: reboring Ø36 and Ø44 with one fine turning head each. (Cost approx. 2 x 1200 €). Circular milling of the chamfer. The tolerances are too tight for the use of fixed tools without adjustment.

New: 3 Lothmann step drills invested at 578 € each. The plate seats can be matched in diameter with stepped shims. 2 tool changes and 2 magazine positions saved. Running time reduced by 1.6 minutes per part.

Example savings:

- 2000 parts x 1.6 min x 1.4 €/min

- 4.480 €

- 3 Lothmann step drills à 578 €

- - 1.734 €

- 2 fine adjustment heads saved

- + 2.400 €

- Profit

- 5.146 €

+ Running time reduced by 47 hours

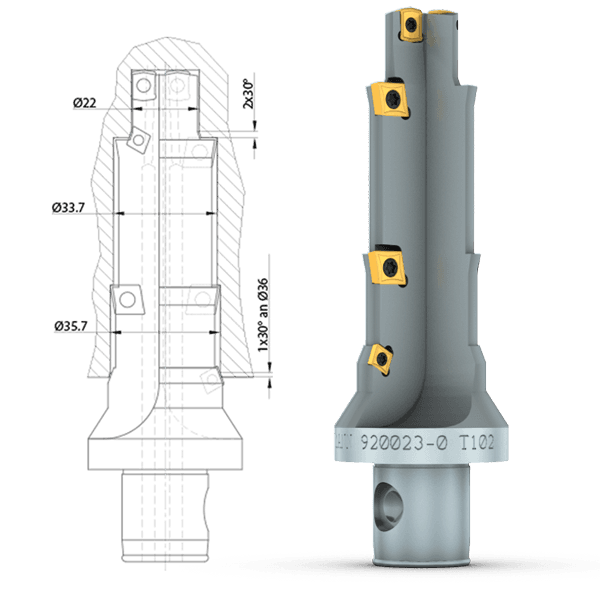

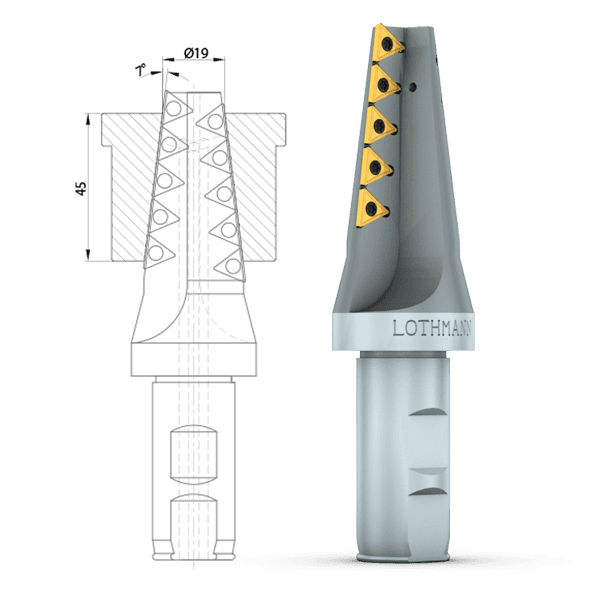

Solid drilling

Regrinding not required Running time 36% reduced

Pre-machining of a connection hole in a manifold cover made of GGG40. The two fits are then reamed.

Previous: Pre-drilling Ø22 with indexable insert drill, re-drilling Ø33.7 and Ø35.7 and 2 chamfers with brazed carbide countersink.

New: 4 Lothmann step drills invested at 778 € each. Complete machining into the solid without pre-drilling. No need for regrinding thanks to replaceable ISO cutting inserts. Higher cutting data due to up-to-date coatings and cutting edge geometries.

Example savings:

- 6500 parts x 0.45 min x 1.80 €/min

- 5.265 €

- Regrinding costs approx. 6 x 240 €

- 1.440 €

- Savings

- 6.705 €

+ Running time reduced by 49 hours

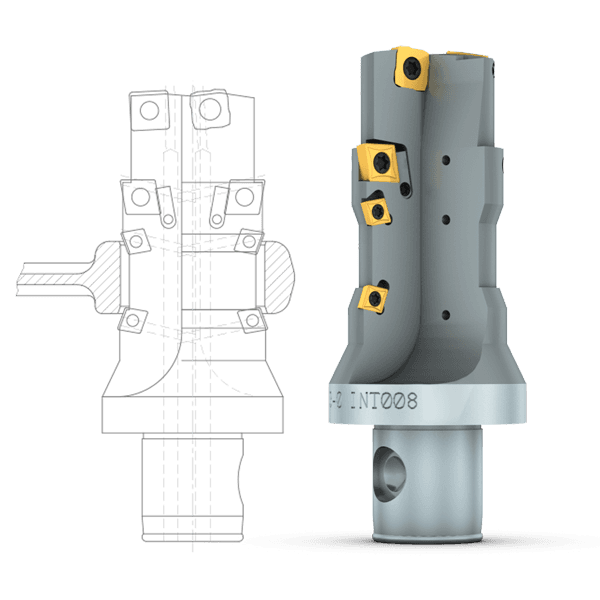

24 seconds faster per connecting rod

Full boring, prefinishing and 2 x chamfers of the small eye on one connecting rod.

Previously: full drilling, then reboring, then both chamfers circular milling with 4 different tools.

New: 6 Lothmann step drills invested at 648 € each. The prefinishing fit is matched in diameter with stepped shims. 3 tool changes and 1 circular path saved. Running time reduced by 0.4 minutes per part.

Example savings:

- 60,000 parts x 0.4 min x 1.2 €/min

- 28.800 €

- 6 Lothmann step drills à 648 €

- - 3.888 €

- Profit

- 24.912 €

+ Running time reduced by 400 hours p.a.

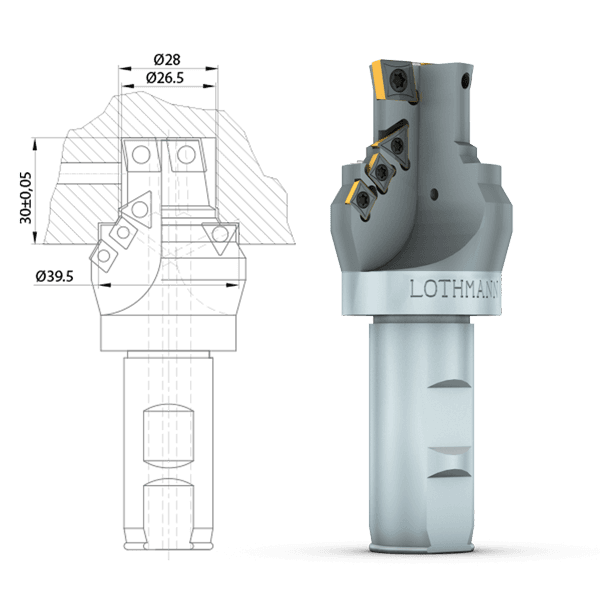

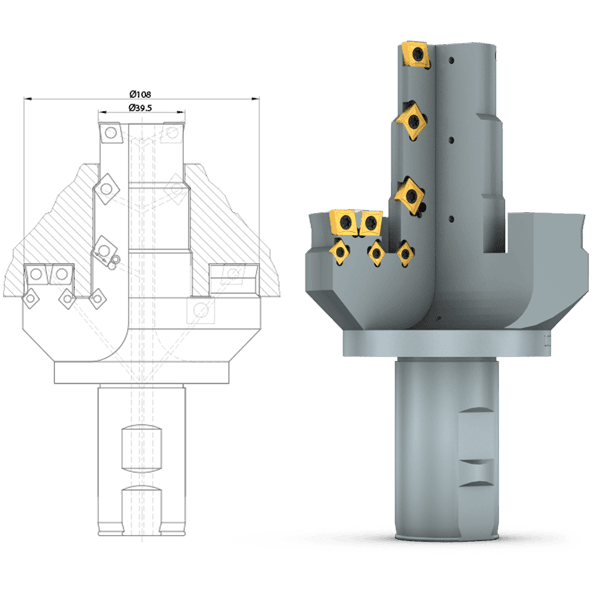

Counterbore

Form drilling of a cartridge hole in a hydraulic block made of GGG50.

Previous: predrilling Ø26, circular milling countersink Ø26.5, Ø28 and Ø39.5, circular milling 3 chamfers.

New: 3 Lothmann step drills invested at 516 € each. 3 tool changes and 2 magazine places saved. Running time 2.2 minutes shorter.

Example savings:

- 900 parts x 2.2 min x 2.1 €/min

- 4.158 €

- 3 Lothmann step drills à 516 €

- - 1.548 €

- Profit

- 2.610 €

+ Running time reduced by 33 hours

Back Countersinking

Alignment correct + reclamping saved

Machining of a slide bore on both sides. Required alignment tolerance of the 3 diameters of 0.05 mm.

Previously: Drill Ø20, ream Ø30 with chamfer, ream 2 screw holes on H7 as auxiliary fits for reclamping, machine Ø30 with chamfer in additional clamping.

New: 3 Lothmann combi countersinks invested at 741 € each. Drilling Ø20. Front and rear machining of both Ø30 with chamfers in one operation. Second set-up eliminated altogether.

Example savings:

- 700 parts x 3 min x 2.70 €/min

- 5.670 €

- 3 Lothmann step countersinks à 741 €

- 2.223 €

- Profit

- 3.447 €

+ Running time reduced by 35 hours

Reverse counterbore

Reverse countersinking of a gate valve bore in a cast steel valve body.

Previously: retracting a long milling arbor and manually attaching an HSS countersink when the machine stopped.

New: 2 Lothmann reverse countersinks invested at € 530 each. No machine stop. 6 minutes of running time saved.

Example savings:

- 400 parts x 6 min x 1.40 €/min

- 3.360 €

- 12 slip-on cutters a 75 € saved

- 900 €

- 2 Lothmann step drills at 530 € each

- - 1.060 €

- Profit

- 3.200 €

+ Running time reduced by 40 hours

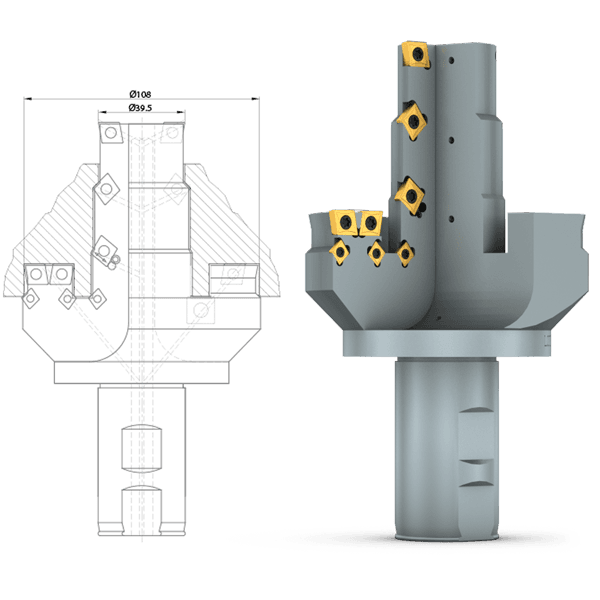

Overwind

11 minutes faster per part

Producing 5 diameters, 5 chamfers and 2 flat surfaces on one filter head.

Previously: rough turning of Ø39.5 and 44.5 with double-fluted cutters, circular milling of the remaining diameters and chamfers with end mills and chamfer cutters, respectively.

New: 2 Lothmann step drills at 1550 € invested. 3 tool changes are eliminated and 3 magazine positions are freed up. Running time is reduced by 11 minutes.

Example savings:

- 2 Lothmann step drills à 1550 €

- 3.100 €

- Savings per part 11 min x 1,80 €

- 19,80 €

- Amortization from 3100 €/ 19,80 € = 157 parts

- Profit after 500 parts

- 6.800 €

+ Running time reduced by 92 hours

Bell tool

Pre-turning of a forged gear shaft in large-scale production.

Previously: Overturning with turning steel in 4 paths.

New: 8 Lothmann overturning tools invested at 683 € each. Cycle time reduced by 11 seconds.

Example savings:

- 300,000 parts x 0.183 min x 1.4 €/min

- 76.860 €

- 8 Lothmann bell tools à 683 €

- 5.464 €

- Profit

- 71.396 €

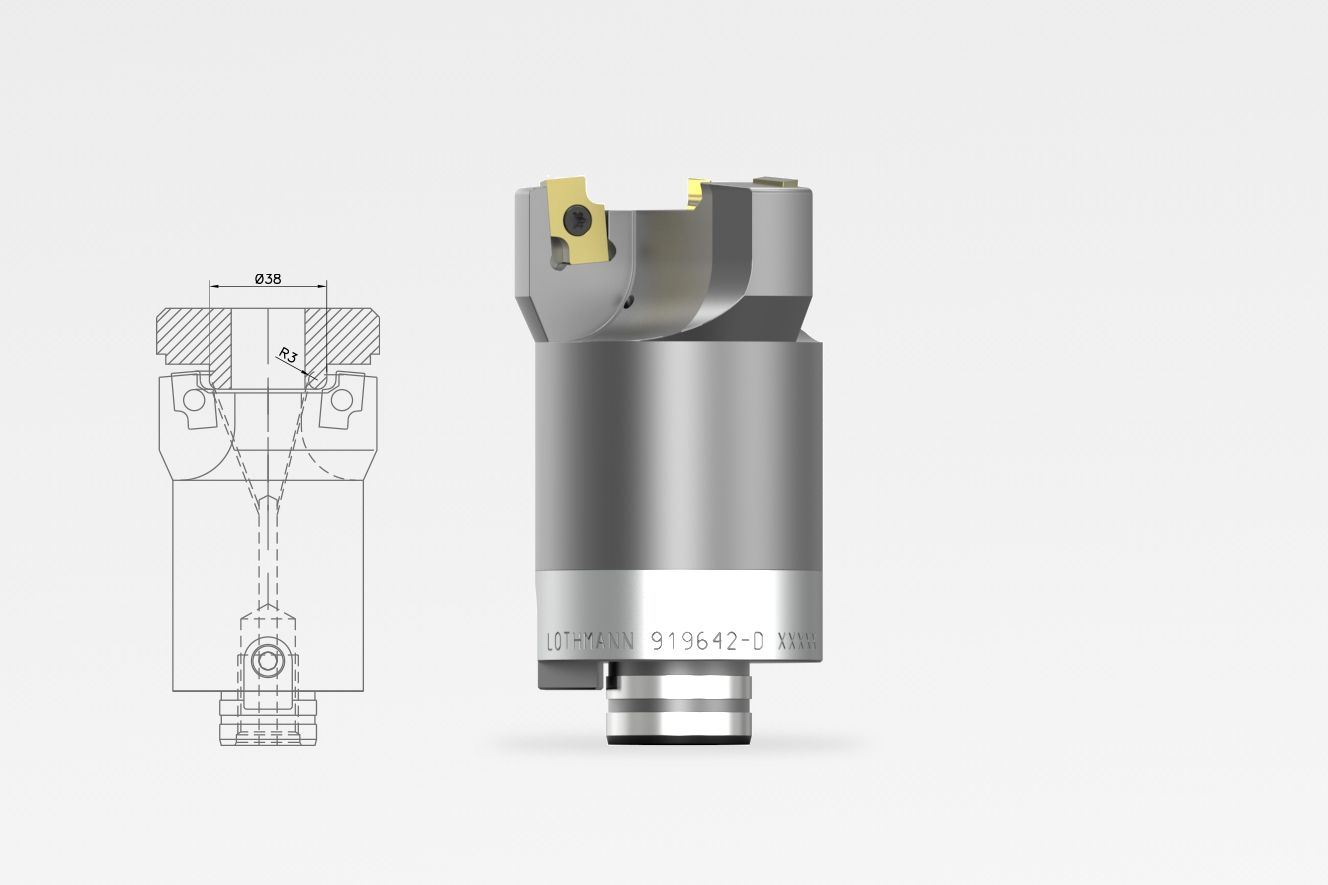

Special cutting

60% machining time reduced

Milling outer radius with special cutting edges in a bell cutter.

Previously: solid carbide radius tool R3 with Ø12 with Z=4 -> travel approx. 120mm - machining time approx. 12 seconds. Cost 150€ / Stk. 2x in stock as stock.

New: 1x Lothmann bell cutter Z=3 à 650 €/pc. invested plus 10 special WSP à 45 €/pc. -> travel approx. 20mm.

Machining time approx. 5 seconds

- 23,000 parts x 0.12 min x 1.50 €/min

- 4.140 €

- 1 Lothmann bell cutter à 650 € plus 10 WSP à 45 €/pc.

- 1.100 €

- Profit

- 3.040 €

+ running time reduced and no regrinding and stock

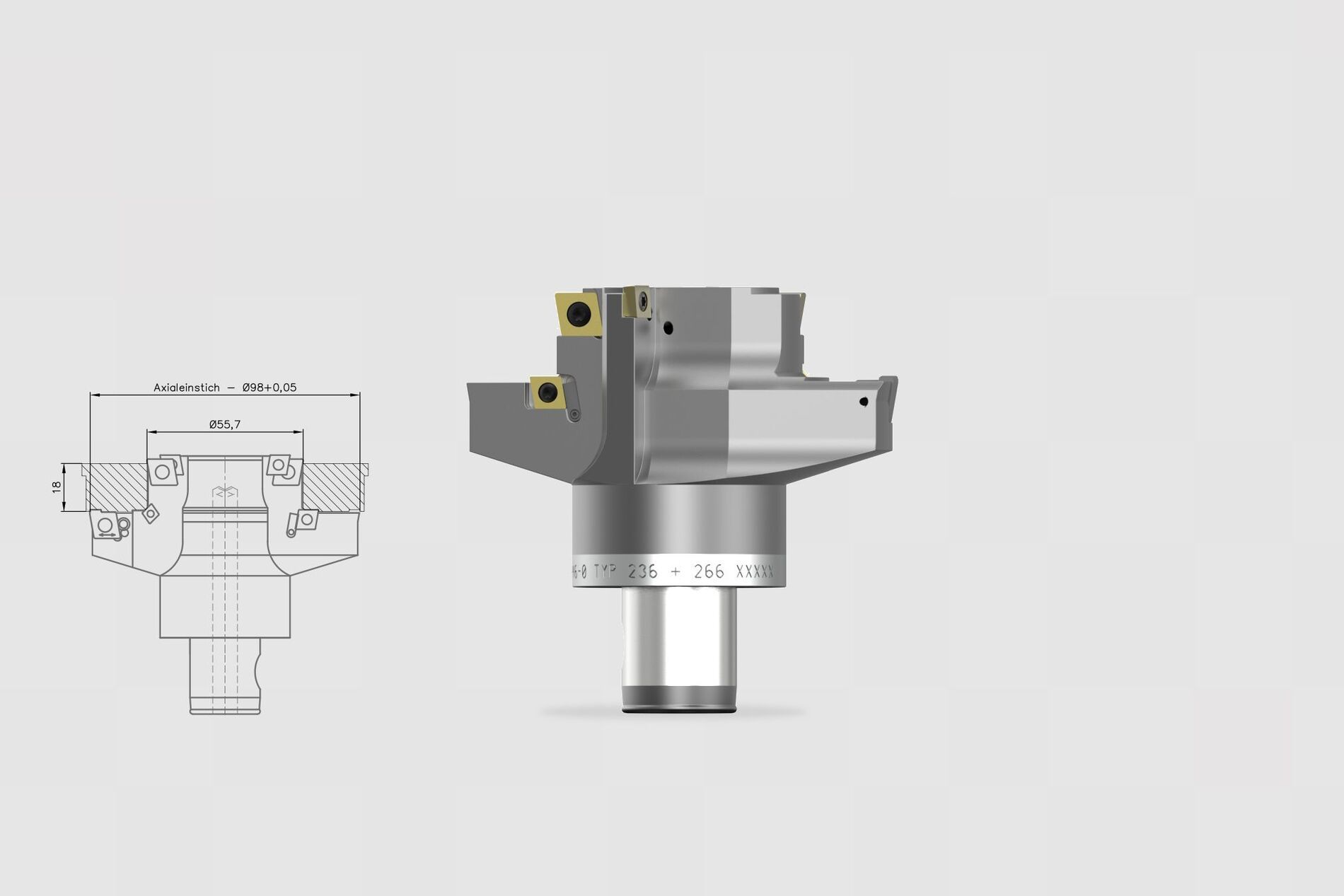

Axial recess by countersinking instead of milling - adjustable diameter

Countersinking of an axial recess Ø98+0,05mm with adjustable special cutting edge plus pre-machining of further diameters

Previously: countersinking Ø55,7mm then face milling. Circular milling of the chamfer and milling of the recess with solid carbide milling cutter Ø5mm -> travel approx. 300mm.

New: 3 Lothmann combination tools at 1,280 € invested plus 10 special cutting edges at 50 €/pc. Result: 3 tool changes and 3 magazine positions saved. Running time reduced by 3.5 minutes per part.

Example savings:

- 2000 parts x 3.5 min x 1.6 €/min

- 11.200 €

- 3 Lothmann step drills à 1.280 € plus special WSP

- - 4.340 €

- Profit

- 6.860 €

+ 3 magazine places saved and no follow-up costs due to fewer carbide tools

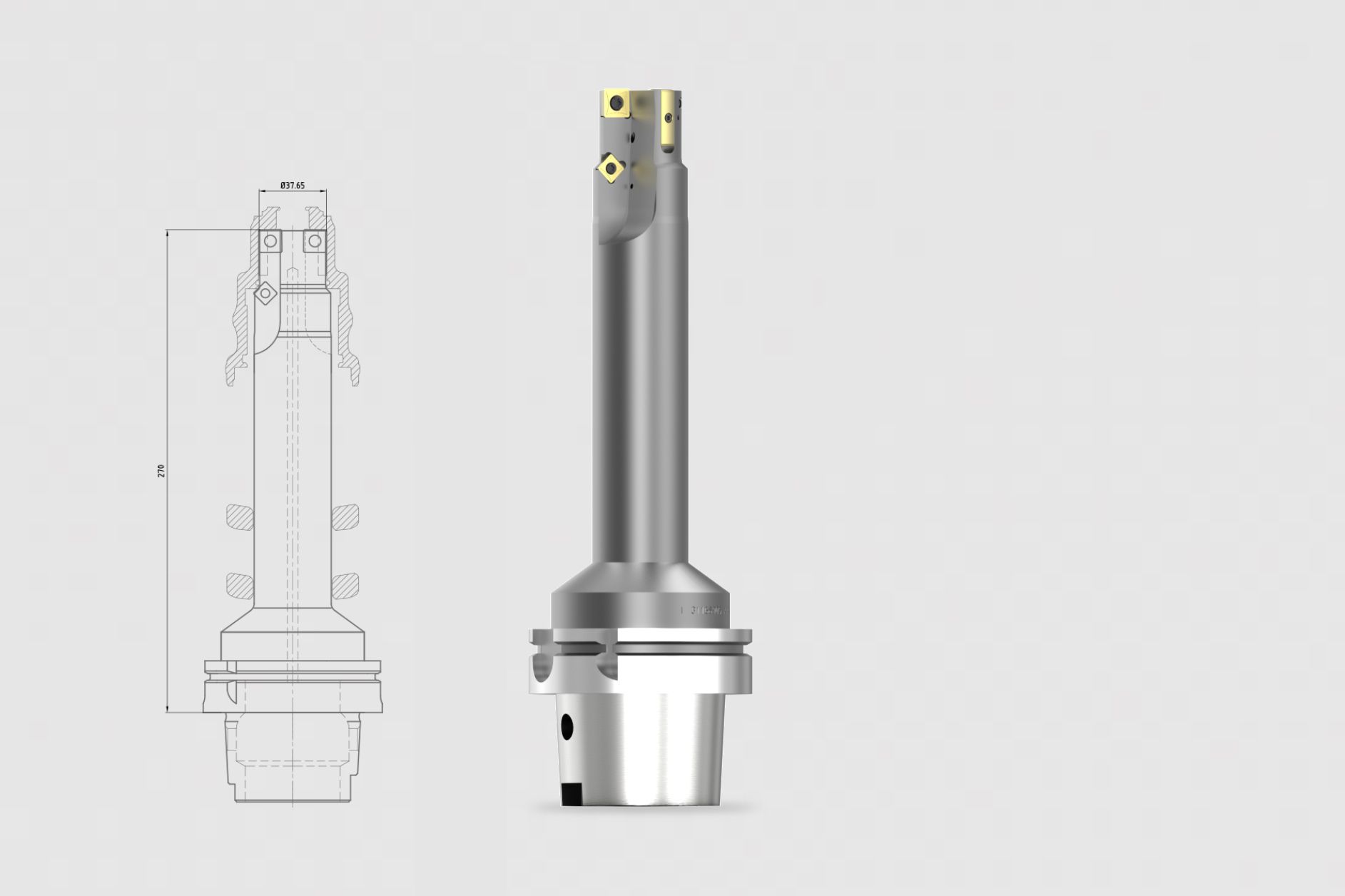

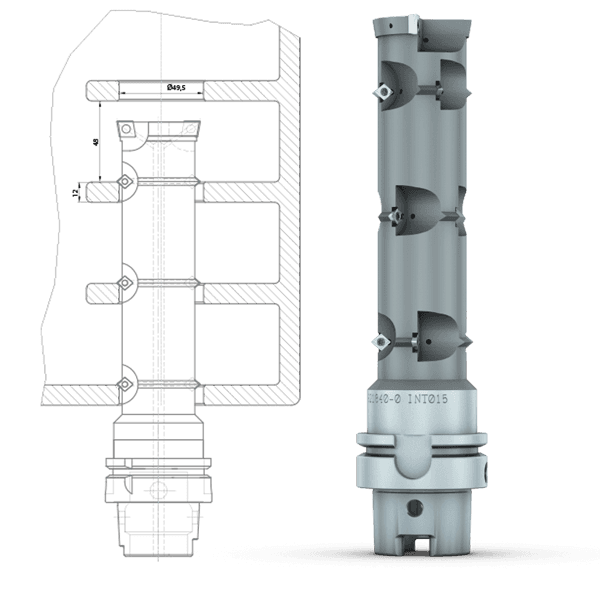

Guide rails

Hard-to-reach fit pre-machined with WSP tool to avoid vibrations incl. guide pads.

Until now: No standard solution available. Alternative: Special adapter with carbide tools in special design.

New: Lothmann special tool in monoblock design HSK100-Form A. Due to the high machining depth and the resulting radial forces through the chamfer incl. guide pads made of carbide. All components demountable and available from stock.

- Savings investment:

- Approx. 2.000 €

+ simple special tool with standardized components.

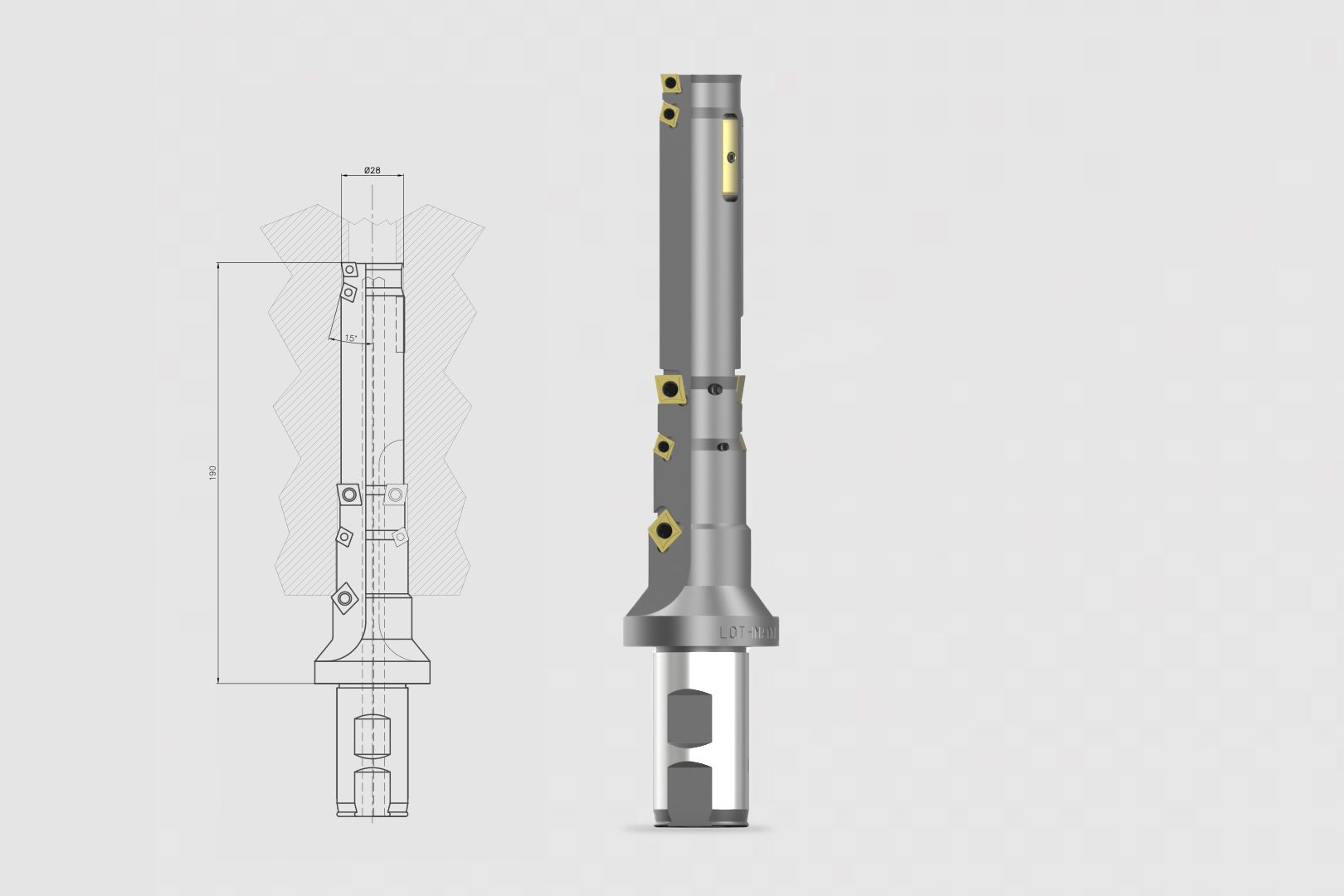

Machining deep holes with multiple diameters and chamfers with reduced vibrations.

Previously: several tools for the individual diameters, additionally 15° cutter in special design.

New: Lothmann special tool with ISO cutting edges and guide pads to absorb radial cutting forces and reduce vibrations during machining. Machining time reduced by 3:50 minutes.

Savings:

- 1,000 parts x 3.83 min x 1.50 €/min

- 5.745 €

- 2 Lothmann step countersinks at 1,150 € each

- 2.300 €

- Profit

- 3.445 €

+ better concentricity of the bore.

Others

Countersink

Pre-drilling of a taper countersink 7° for subsequent reaming on a lathe with bar feeder.

Previous: boring with 2 different boring bars in 4 paths.

New: 3 Lothmann taper countersinks invested at € 680 each. Cycle time reduced by 9 seconds.

Example savings:

- 40,000 parts x 0.15 min x 1.1 €/min

- 6.600 €

- 3 Lothmann countersinks à 680 €

- 2.040 €

- Profit

- 4.560 €

+ Running time reduced by 100 hours

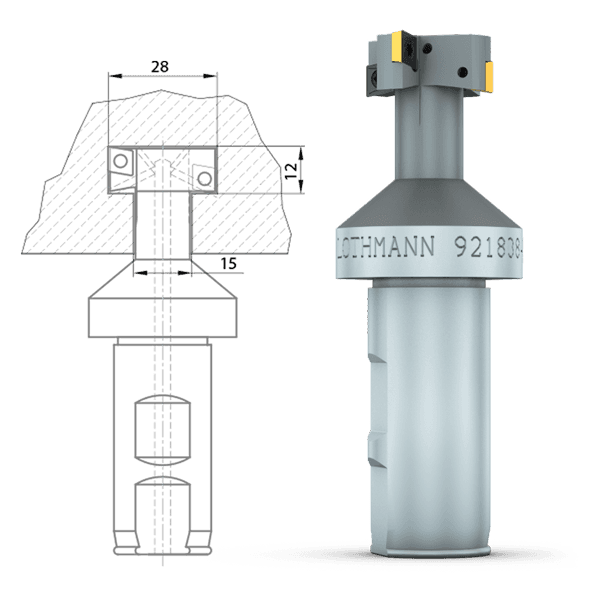

T-slot cutter

Chamfering of a T-slot in a plate made of GG25 in one operation. The width 15 mm is pre-milled.

Previous: Milling of the T-slot with a standard milling cutter in 4 passes.

New: 3 Lothmann tools invested at €454 each. The T-slot is now produced in one milling path.

Example savings:

- 200 parts x 12 min x 1.6 €/min

- 3.840 €

- 3 Lothmann tools à 454 €

- 1.362 €

- Profit

- 2.478 €

+ Running time reduced by 40 hours

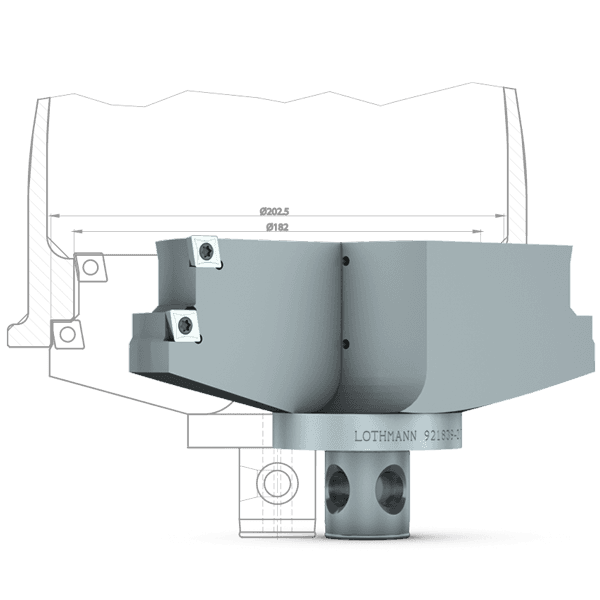

Fixed tools up to Ø210

Pre-machining of a bearing seat on a gear bell made of aluminum.

Previous: circular milling of the 2 diameters and 2 chamfers in a total of 8 circular paths.

New: 2 Lothmann step countersinks invested at 1331 € each. Both diameters and chamfers are now countersunk in 14 seconds.

Example savings:

- 3,6 min x 2,1 €/min

- 7,56 €

- 2 Lothmann step countersinks à 1331 €

- 2.662 €

- Break-even after 2662 / 7.56 =

- 352 Gehäusen

- Profit after 1000 cases

- 4.898 €

+ runtime reduced by 60 hours

Crank lane prefinishing + chamfering

Boring Ø49.5 and chamfering on both sides of 3 bearing shells in an aluminum crankcase.

Previously: Boring with double cutter and separate chamfering in 6 circular movements.

New: Boring and circular milling of 3 chamfers each in 2 circular movements with one tool.

Example savings:

- 24,000 parts x 0.62 min x 1.52 €/min

- 22.618 €

- 3 Lothmann tools à 1397 €

- 4.191 €

- Profit

- 18.427 €

+ Running time reduced by 248 hours

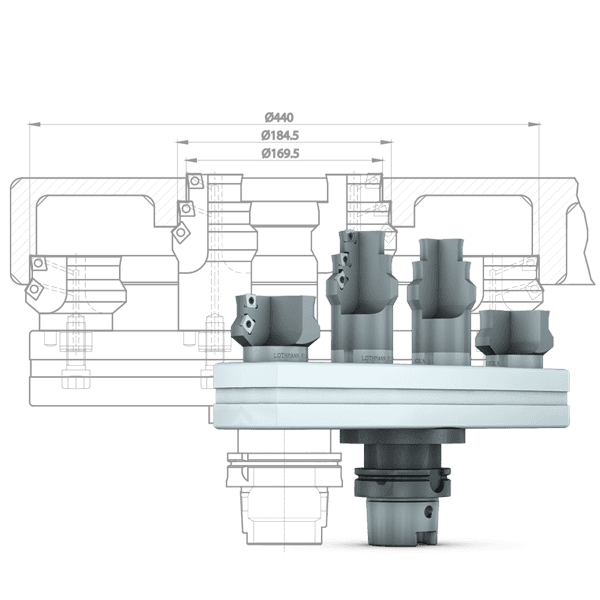

Bridge tool

Boring of 3 diameters and 2 chamfers on an aluminum gear housing on a large BAZ.

Previously: circular milling in a total of 10 circular paths

New: Boring and chamfering of all diameters in one feed path

Example savings:

- 600 parts x 18 min x 2.80 €/min =

- 30.240 €

- 2 Lothmann bridge tools à 3720 € =

- 7.440 €

- Profit

- 22.800 €

+ Running time reduced by 180 hours